Introduction

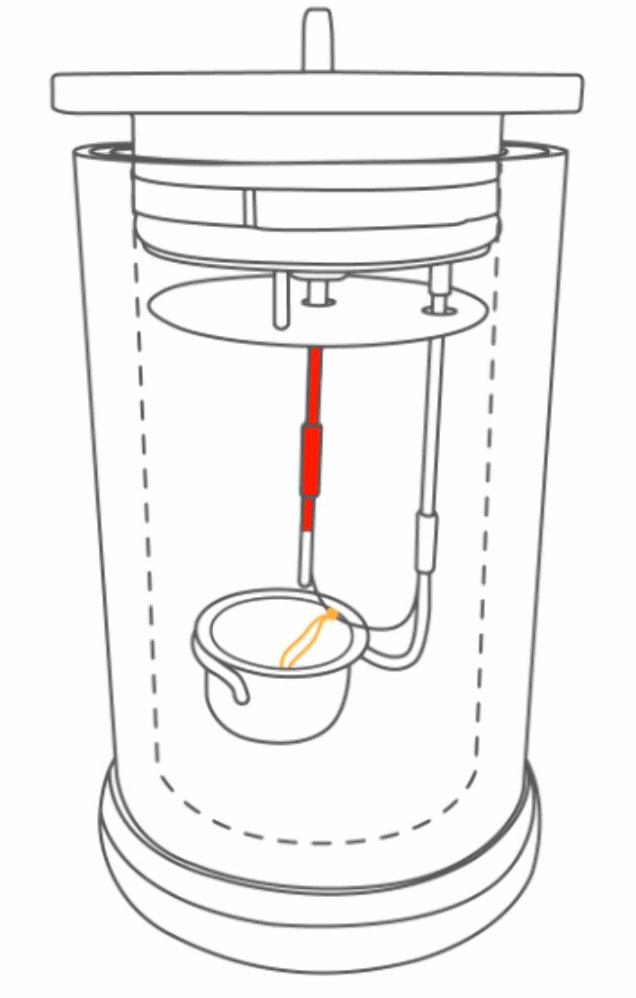

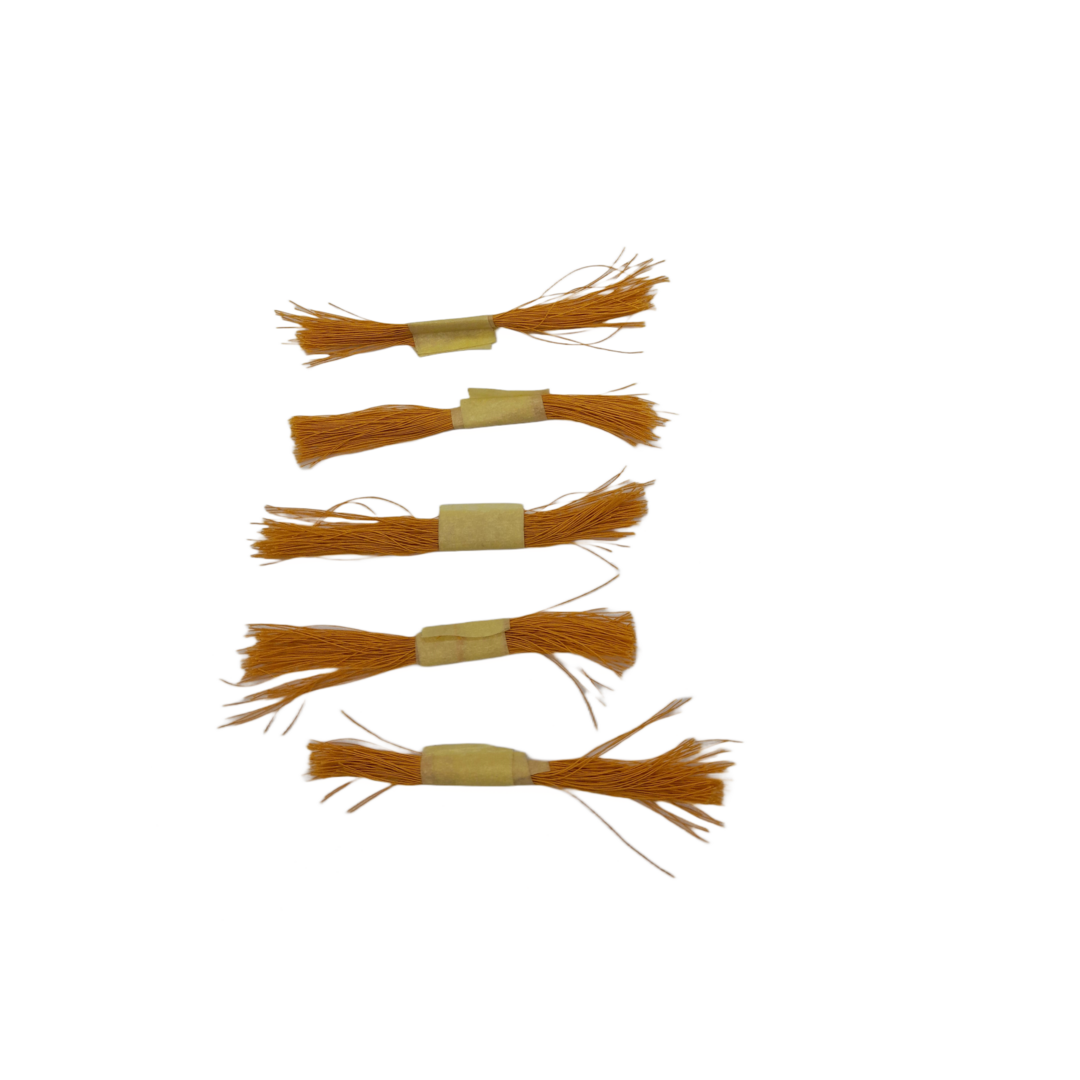

The sample is ignited by sending a high current through the firing wire which heats the wire to approx. 800 degrees °C. This intern ignites the cotton (if used) or the sample directly. For this to work the cotton or the firing wire must touch the sample.

Sometimes samples require the direct firing method. However, this method will melt the wire with every firing.

During the firing, the electrical energy will heat the vessel. For very sensitive applications, this may be important. It is a constant and will only make a difference if the calibration temperature rise is vastly different to the sample rise.

The firing voltage default setting is 25V. It is sometimes advisable to change that setting to suit the sample. The firing wire (with cotton) should last 10 to 30 samples. If not then adjust the firing voltage accordingly.

The CAL3K combines the electrical and the cotton energy in to ‘COTTON + WIRE CORR’.

This should be measured when:

|

The wire changes |

|

The firing voltage is changed |

It should be measured with the cotton if a cotton thread is used. A firing voltage change down to 20V is insignificant to warrant a new firing energy measurement.

How to do it

This should be measured when:

| Change the ‘MISFIRE LIMIT’ to ZERO. This disables it. | |

| Change the ‘COTTON + WIRE CORR’ to ZERO. | |

| Prepare a vessel as normal (with or without cotton) but without sample | |

| Run a determination | |

| At the end remove the vessel and read ‘READ LAST N_RISE’. This is the compensated nett temperature rise. Since the compensation was set to zero (step 2) it is the new cotton and wire correction | |

| Repeat this operation 3 times and enter the average in to the ‘COTTON + WIRE CORR’ field | |

| Set the ‘MISFIRE LIMIT’ to 0.44 °C |

Summary

The ‘Cotton + Wire Correction’ is constant. It is applied to the calibration and the sample. It needs to be measured only when drastic changes are made to the ignition method.