The CAL3K Manual Oxygen Filling Station has a NEW LOOK!

The manual oxygen filling station is manufactured completely in house which saves on costs and results in a reduced final price. It is light weight making it a lot easier to transport from place to place if needed. It is a lot easier to handle and safe (user-friendly). Being manufactured with different materials to those used before, makes it kinder to the environment (environmentally - friendly).

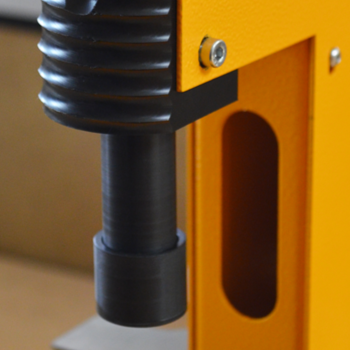

The brass parts have been replaced with Ertacetal (Acetal) which is locally manufactured and cost-effective. The material has a high strength and stability for robust handling, and can withstand a temperature of up to 80°C.

We have replaced the following parts in the new look oxygen filling station to produce a more robust and cost-effective filling station : Gauge Holder, Connections, Pipe Connections, Main Holder, Vessel Holder, Piston, Nozzle Body, Flow Adjustor.

The manual filling station brings a fresh new look to the CAL3K-A and future systems that will require the manual oxygen filling station to fill the vessel for analyses.