The following information applies to the : CAL3K-AP , CAL3K-A , CAL3K-F.

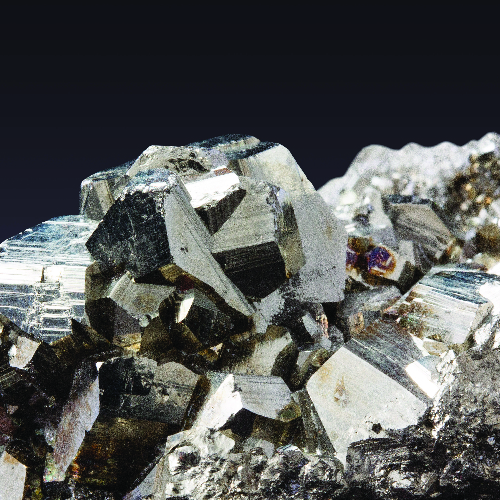

The sulphur correction is required if the sample contains sulphur. In the presence of high pressure oxygen some of the sulphur will be converted to SO2 and some heat will be released in the conversion process. This extra heat release is removed with the sulphur correction. The sulphur correction is proportional to the sample mass and sulphur content. The sulphur correction can be set to zero.

Type: SULPHUR CORRECT, Enter, value, Enter

|

Exit, Clear command entry |

|

Start of command, Sulphur Correction |

|

Accept Command |

|

Enter sulphur value |

|

Accept Value |

The Default setting is 0.0MJ/Kg

The entry of the sulphur correction is password protected (default).

The Sulphur correction is NOT used during calibration.

ZERO THE PRESSURE TRANSDUCER

The pressure transducer which monitors the vessel pressure for Filling and oxygen leakage needs to be offset adjusted so that it reads ZERO at atmospheric pressure.

Learn MoreCOMPENSATION

The CAL3K calorimeter range has two main compensations: Firing Wire and Cotton Compensation & Sulphur Compensation. Sulphur Compensation : Compensates for the formation of sulphuric acid. Entry in Kj/g. Default : 0Kj/g. It is disabled during calibration and calibration check.

Learn MoreCOTTON & WIRE CORRECTION

The sample is ignited by sending a current through the firing wire. This makes the wire glow, which in turn ignites the cotton thread, which in turn ignites the sample. The cotton and wire correction compensates for the electrical firing wire energy and the energy of the burned cotton. The default setting is 0.08°C.

Learn More